The range of safety shell-and-tube heat exchangers is based on the “three chamber devices” principle, which was developed

and patented by the company’s founder Karl-Heinz Funke.

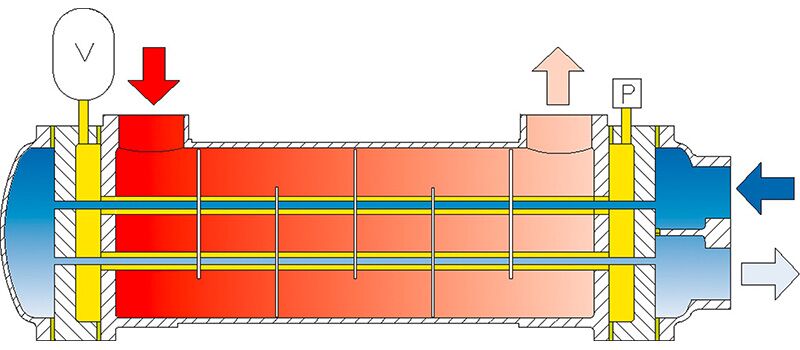

OPERATING PRINCIPLE OF A SAFETY HEAT EXCHANGER

Here with double tubes, double sheets and leak sealing liquid

DESIGN FEATURES

Our customer-oriented, individual solutions in the area of shell-and-tube heat exchangers find their main application in project business.

The focus throughout is always on the customer’s requirements for our products.

We look at the operating data, construction regulations and specifications in the course of project engineering and use this information to provide the optimal, thermodynamic apparatus.

APPLICATION

We attach great importance to a technically and economically optimized solution, one that fully meets the requirements of the customer as well as our requirements for maximum plant safety and efficiency.

After all, at up to 600 bar operating pressure, every single welding seam counts.

In addition, strict quality controls from incoming goods to shipping ensure that the manufactured product meets your requirements with regard to function, quality and documentation.

FUNKE OFFERS THREE VERSIONS FOR DIFFERENT REQUIREMENTS: